Aplicații ale ceramicii cu nitrură de siliciu cu diferite procese de sinterizare

Times New Romanceramică de aluminăTimes New Roman

ceramica din zirconiu

,

Times New RomanTimes New Romancarbură de siliciu

Times New Roman

Times New Roman

However, hot pressing sintering also has disadvantages such as high production costs, complex sintering equipment requirements, and the presence of anisotropic properties due to uniaxial pressure during sintering.

3、Pressureless Sintering Method

Pressureless sintering involves using α-Si3N4 as raw material under standard atmospheric pressure, adding a certain amount of sintering aids for liquid-phase sintering. During sintering, α-Si3N4 transforms into β-Si3N4, and the structure of silicon nitride grains changes from equiaxed crystals to columnar crystals, thereby enhancing the properties of the samples.The advantage of pressureless sintering is its relatively simple preparation process and lower cost, resulting in high-performance silicon nitride ceramics. However, the drawback is that the samples may experience significant shrinkage after sintering, leading to cracking and deformation.

Silicon nitride ceramics prepared by pressureless sintering are widely used in the production of sealing rings, roller rings in the metallurgical industry, vessels for carrying molten metals, and troughs.

4、Gas Pressure Sintering Method

Gas pressure sintering is typically conducted at pressures of 1 to 10 MPa and temperatures around 2000°C, slightly higher than other sintering methods. Even with fewer sintering additives, this method can promote the growth of Si3N4 grains, resulting in samples with elongated columnar grains, high density, and high strength.

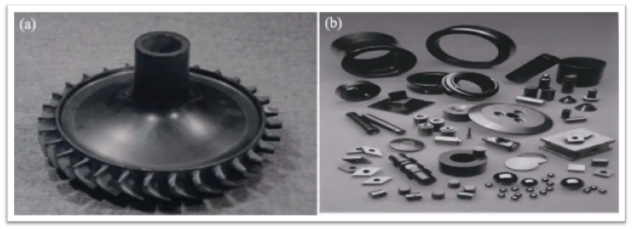

Utilizing gas pressure sintering, products with various complex shapes can be formed and sintered, thus having broader applications compared to silicon nitride ceramics prepared by other processes.

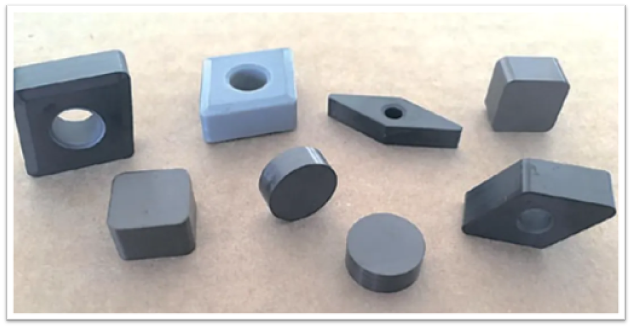

In addition to thermocouple protection tubes, crucibles for metal smelting, rocket nozzles, ceramic cutting tools, bearing balls, sealing rings, roller rings in the metallurgical industry, and vessels for carrying molten metals, silicon nitride ceramics produced by gas pressure sintering are also extensively used in various high-temperature and high-stress components in ceramic turbine engine parts, such as stator blades, rotor blades, and casings.

5、Hot Isostatic Pressing (HIP) Sintering Method

Hot isostatic pressing involves the simultaneous application of high temperature and isotropic high-pressure gas to ceramic powders, compacts, or pre-sintered bodies to achieve sintering densification.

Combining the advantages of hot pressing and pressureless sintering, hot isostatic pressing can produce silicon nitride ceramics with high density and complex shapes. However, due to expensive equipment, complex production processes, and high technical requirements, it is primarily used for manufacturing high-end silicon nitride products, such as silicon nitride bearing balls.

Moreover, silicon nitride ceramics prepared by hot isostatic pressing have significant potential applications in fields demanding high-performance products, such as micro-bearing applications in infrared detectors.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.